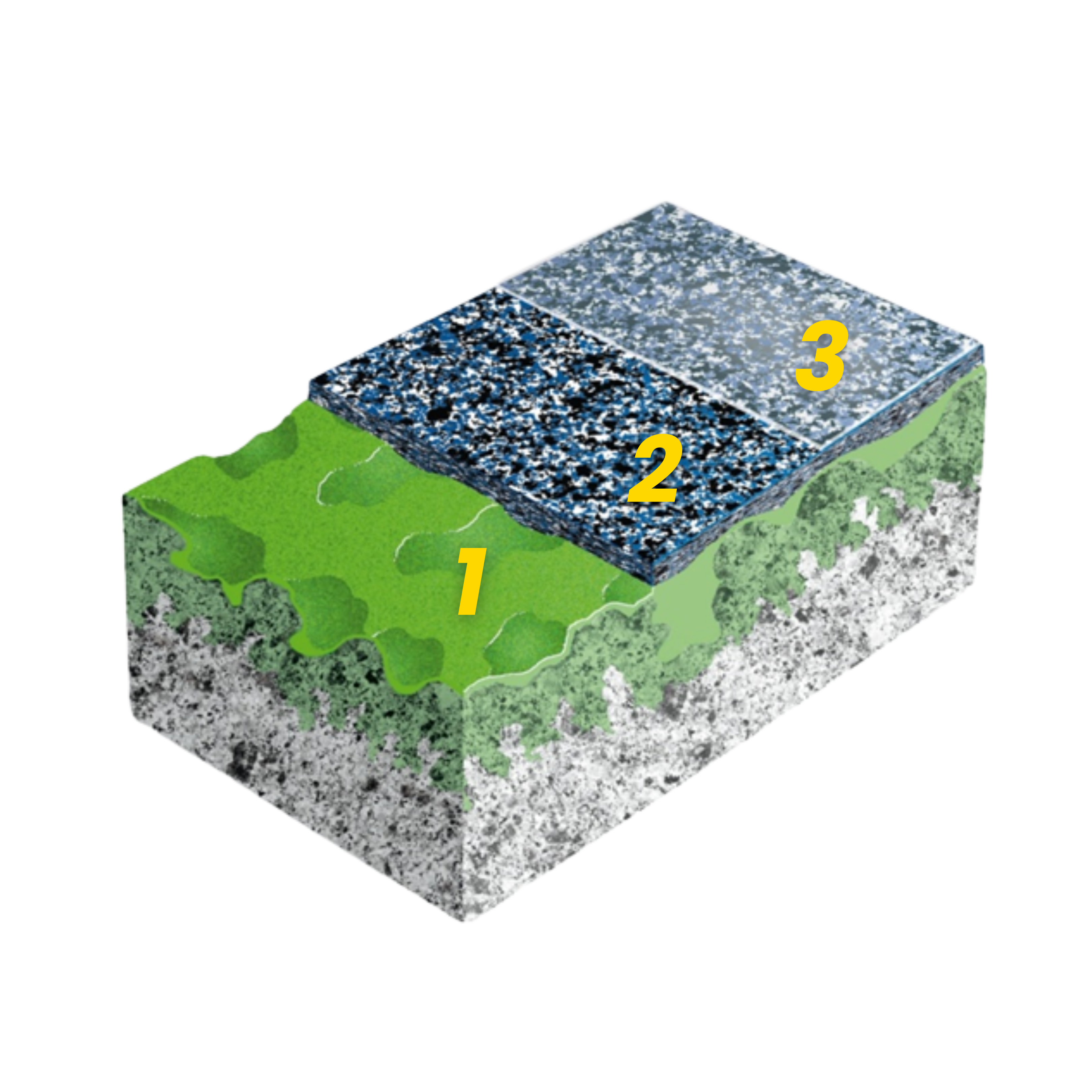

1

Engineered to Work Overnight

KITCHGUARD™ uses Advanced German-Engineered Technology, a slipless, seamless, ultra-durable flooring system

that cures fully in just 6 hours. That means no shutdown, no demolition and a floor that's certified for

HALAL, GMP, HACCP and in conformity to the strict quality requirements of ISO 9001:2000 & under a qualified

ISO 14001:2005 environmental management system, ready for audit the next morning. This is why KITCHGUARD™

can be installed overnight and returned to operation without disruption.

2

Why Seamless Is Non-Negotiable

What Commercial Kitchen Flooring Truly

Requires?

All commercial kitchen flooring must meet essential requirements such as durability, slip resistance, fire

protection, stain resistance and ease of maintenance.

However, there is one critical requirement that is often overlooked: the floor must be completely seamless.

Why Seamless

Matters?

In commercial kitchens, even a microscopic pinhole can allow bacteria, mold, fungus, insects, and moisture

to penetrate beneath the surface. Once this occurs, the subfloor becomes compromised, creating hygiene

risks, foul odors, audit exposure and long-term structural damage. That is why a truly non-porous, seamless

flooring system is essential for any commercial kitchen that must remain Safe-to-Work, compliant and

audit-ready.

3

How KITCHGUARD Prevents Contamination at the Source

KITCHGUARD™ delivers a fully seamless, non-porous flooring system, sealed against even microscopic

penetration.

This prevents the ingress of:

- Bacteria

- Mold and yeast

- Moisture and contaminants

Helping kitchens maintain a hygienic, controllable and audit-ready working environment. The system contains

no solvents and no VOCs, allowing installation within occupied buildings without disrupting operations.

4

Built for Real Commercial Kitchen Abuse

Designed for Real-World Conditions

Commercial kitchens expose floors to extreme conditions every day:

- Heavy equipment and rolling loads

- Chemical and oil exposure

- Repeated impact from dropped utensils, pots, and cookware

KITCHGUARD™ is engineered to withstand all of the above without cracking, gouging or premature failure.

This is how the system remains stable under continuous, high-pressure daily use.

5

Safety, Comfort and Compliance Together

Designed for People Who Work on the

Floor

KITCHGUARD™ systems are available in multiple anti-slip grades and finishes, ensuring safety without

compromising cleanability.

The seamless surface enables:

- Faster washdowns

- Easier maintenance

- A safer and more comfortable working environment

This makes KITCHGUARD™ suitable for environments where hygiene, safety and operational continuity are

non-negotiable, including:

- Commercial kitchens

- Central kitchens

- Hospitals and medical facilities

- Food manufacturing environments

- Schools, bakeries, and institutional kitchens

6

Why Waiting Is Designed Out of the System

A System Designed Not to Wait

Unlike conventional flooring systems that require prolonged curing and shutdowns, KITCHGUARD™ is engineered

around a different assumption: Commercial kitchens cannot afford to stop.

With full curing in just 6 hours, KITCHGUARD™ allows kitchens to be installed overnight and returned to

operation the next day - Safe-to-Work and audit-ready.

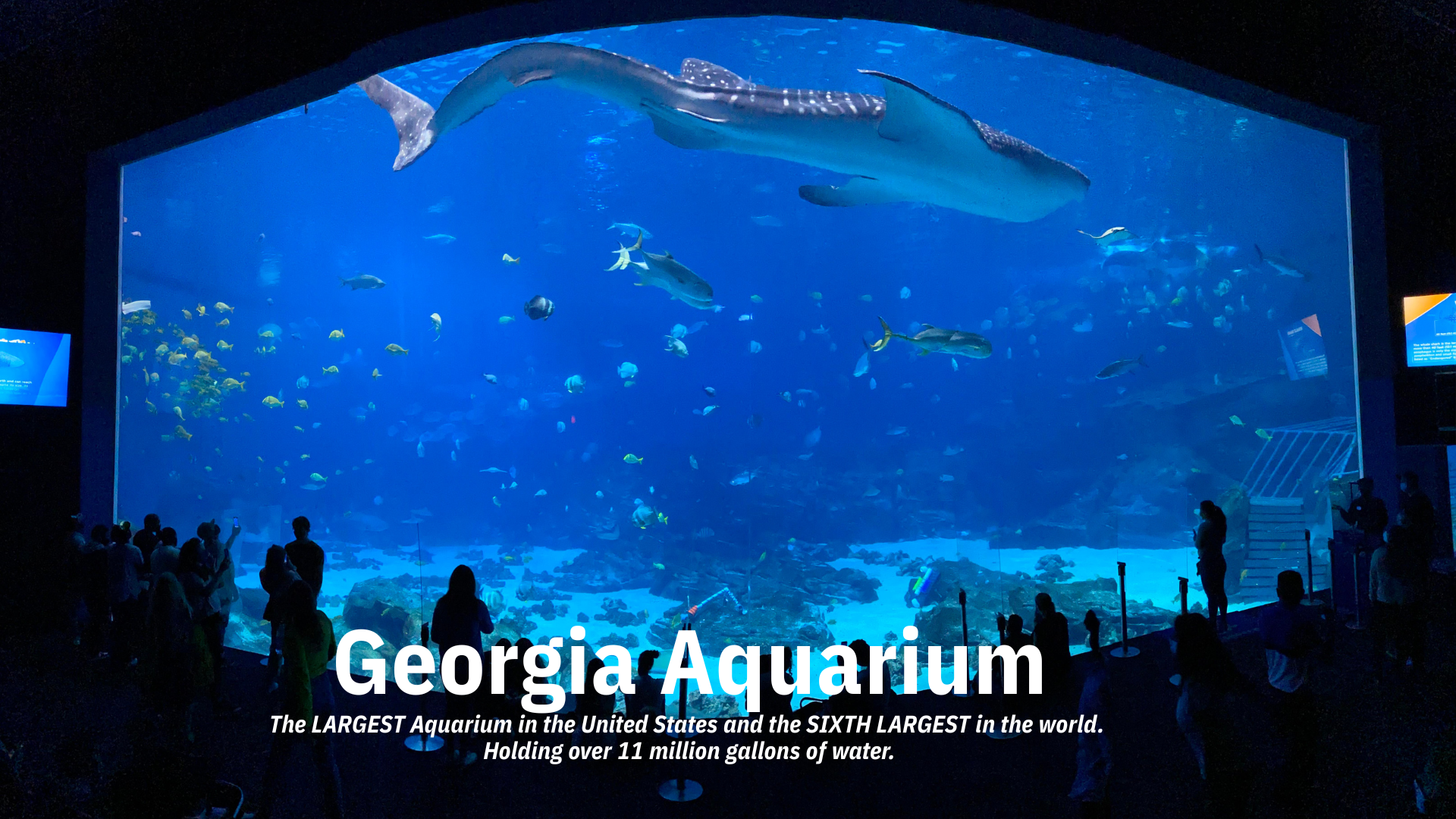

7

Strength at a Structural Level

Engineered Reliability You Can Depend

On

According to the Georgia Aquarium, acrylic is 17 times stronger than glass. It is not glass holding back

millions of gallons of water but the same core reactive resin technology used in KITCHGUARD™ flooring

systems.

This acrylic-based reactive resin forms the structural backbone of KITCHGUARD™, delivering exceptional

strength, durability and resistance under extreme commercial kitchen conditions. This is not surface

strength. It is engineered for reliability.